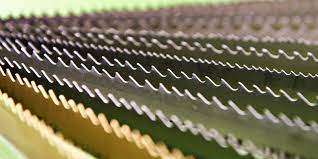

Choosing Metal Bandsaw Blades Based On Teeth Characteristics

When I’m trying to get the best cuts possible from my metal bandsaw blades , there’s a few key things I need to know about the blade teeth. The size, spacing, angle, and shape can all affect how well it cuts, how precise the cut is, and how long the blade lasts.

Tooth size is mega important. Large teeth can handle small cross sections no problem, but small teeth will struggle with bigger stuff. One thing I gotta avoid is teeth too small for the material – they just get clogged up before even finishing the cut.

Instead of cutting, the blade rubs against the metal, making crazy heat and wearing down the blade real quick. Picking the right tooth size means the blade stays efficient and lasts way longer.

The spacing, or pitch, is crucial too. For thin pieces, I want a fine pitch with lots of teeth. But for thick stuff, a coarse pitch with fewer teeth is better. Generally I need a minimum of 3 teeth in the cut at a time. But 6 to 12 engaged teeth is the prime zone. I also check if it’s a constant or variable pitch. Constant means the teeth are all spaced the same – good for general use. Variable means alternating tooth size and gullet depth – helps with noise and vibration when cutting structural materials and tubes.

Tooth angle, or rake, affects precision. Positive rakes are great for thick solids and heavy-wall tubes. Less positive or straight rakes work better for structural cuts and bundles. Matching the right rake to the material helps the blade cut super efficiently and accurately.

Lastly, tooth shape gives different perks. Regular teeth with a straight zero rake handle general tasks awesomely. Hook-shaped teeth with 10 degree positive rake are killer for fast non-ferrous metal cutting. Skip-shaped teeth have straight rakes and shallow gullets – perfect for big sections of non-ferrous metals.

Taking the time to pick teeth that fit my needs makes a huge difference in cutting performance. Whether I need intricate precision or fast material removal, customising the size, pitch, rake and shape to the job helps my metal bandsaw blades last longer and just straight up work better. Really dialling in those tooth details is how I max out efficiency and quality on all my metal cutting projects.